The Joint Strike Fighter is one of history’s most costly failures

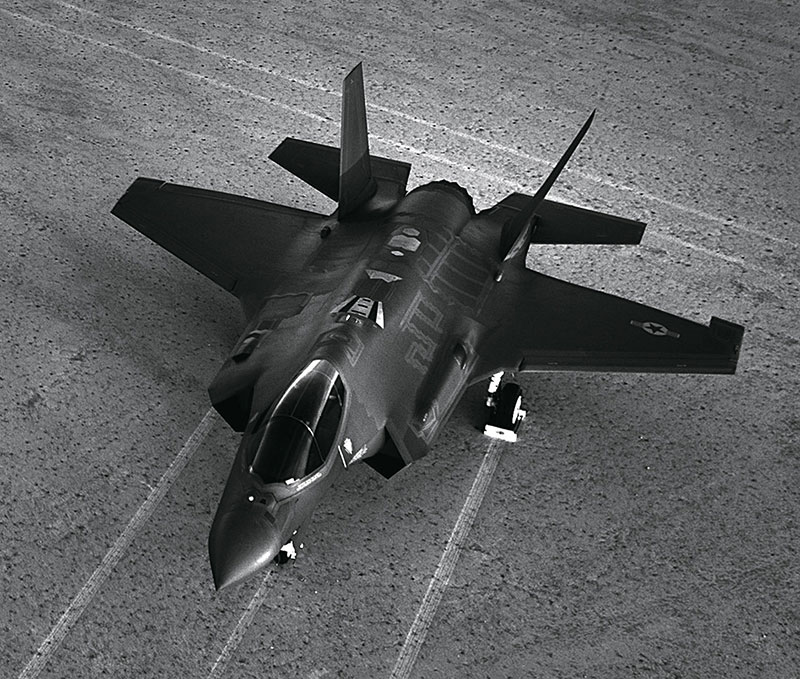

One of the most ambitious and troubled military hardware projects in history, the Lockheed Martin F-35 Lightning II is as spectacular as it is expensive

A multitrillion-dollar failure, the Joint Strike Fighter has met almost none of its initial aims

In 1993, the US military began what would become the single most expensive individual military procurement project in history. With an expansive and varied fleet of ageing fighter jets, Clinton administration Secretary of Defence Les Aspin suggested the next generation of planes should be standardised to keep costs to a minimum.

Almost 25 years and approximately $400bn later, combat-ready Lockheed Martin F-35 Lightning II jets have only just started being delivered to countries that have been waiting decades on their orders. While the F-35 is impressive, the project has been marred by an out-of-control budget and a never-ending stream of setbacks.

Almost 25 years and approximately $400bn later, combat-ready Lockheed Martin F-35 Lightning II jets have only just started being delivered

Search and destroy

After a lengthy tendering process, in 2001 Lockheed Martin won the contract to build what had been dubbed the ‘Joint Strike Fighter’. The codename came from the requirement that the countries and military branches purchasing the jets should be able to order variants on the same base design to keep costs low.

Lockheed’s prototype became the F-35 Lightning II, and is designed in three main variants. The F-35A is the base model for use by the US Air Force – a modern stealth fighter. The variant for use by the US Marines is the F-35B, and is capable of taking off and landing vertically, replacing the Harrier Jump Jet. The F-35C is the US Navy version, and is able to operate out of an aircraft carrier thanks to its folding wings and shorter runway requirements. All three feature a ‘combat cloud’ system that allows a fleet of F-35s to share and compile tactical information, as well as helmets that let pilots see through the floor of the jet via a series of cameras. The Joint Strike Fighter was expected to result in huge cost savings, with Australia, Canada, Denmark, Italy, the Netherlands, Norway, Turkey and the UK all signing up as customers. Despite best intentions, however, the project proved to be anything but cheap.

Master of none

Being designed to fill such a wide variety of roles, the F-35 became bloated and ineffective. The US Air Force wanted a stealth fighter to slip under enemy radars, similar to jets used by Russia and China. The Marines demanded a jet that included internal weapons and vertical take-off systems. Meeting these requirements made the overall design of the F-35 far more bulky than initially envisioned.

F-35A

Features: Refuel door, four-barrel Gatling gun

Length: 15.7m

Height: 4.4m

Wingspan: 10.7m

Weight: 13,290kg

F-35B

Features: Probe refuel basket, vertical take-off

Length: 15.6m

Height: 4.4m

Wingspan: 10.7m

Weight: 14,651kg

F-35C

Features: Folding wings, short runway optimised Length: 15.7m

Height: 4.5m

Wingspan: 13.1m

Weight: 15,785kg

Making matters worse, the US also wanted to keep costs low by building production planes while testing was still underway. As more planes were built, more problems emerged. In 2004 the F-35B was found to be more than 2,000lbs overweight, and in 2012 the US was forced to approve plans for reduced mobility and longer runways to accommodate necessary design changes. By 2013, the cost to retrofit planes already built was estimated at $1.7bn, and in 2014 the entire fleet was grounded after an engine fire. Some reports have even suggested that, while the F-35 features greater stealth capabilities, in a one-on-one dogfight, an ageing F-16 may actually come out on top.

The F-35 seems to be a textbook case of the sunk-cost fallacy: investors believe they can’t cancel a large project no matter how disastrous it may be because everything already spent would be for nothing. It may be President Trump who decides the ultimate fate of the jet, and he has already fired off several angry tweets pledging he will bring down the per-plane cost or cancel the entire project.

The F-35 program and cost is out of control. Billions of dollars can and will be saved on military (and other) purchases after January 20th.

— Donald J. Trump (@realDonaldTrump) December 12, 2016

Following these tirades, Lockheed reportedly cut $600m from the next 100 planes to be delivered, though officials claimed this was due to mass production naturally driving down prices. Either way, it may only be a drop in the ocean, with Reuters reporting in 2012 that the lifetime cost of the project is expected to reach $1.45trn.