TOMRA continues its drive to create a plastics circular economy

Plastic is one of the world’s most useful materials, but at present, it is being grossly mismanaged. By closing the plastics loop, manufacturers can ensure the resource is responsibly recycled and reused

To ensure plastics are kept within a closed loop, TOMRA says demand for post-consumer recycled materials must be created: as the demand increases, so does the value of the material, making it more economically viable to recycle

An increase in consumer demand, pledges from high-profile companies and new legislation around the use of recycled materials highlight how steps are being made in the right direction when it comes to sustainably using the planet’s resources.

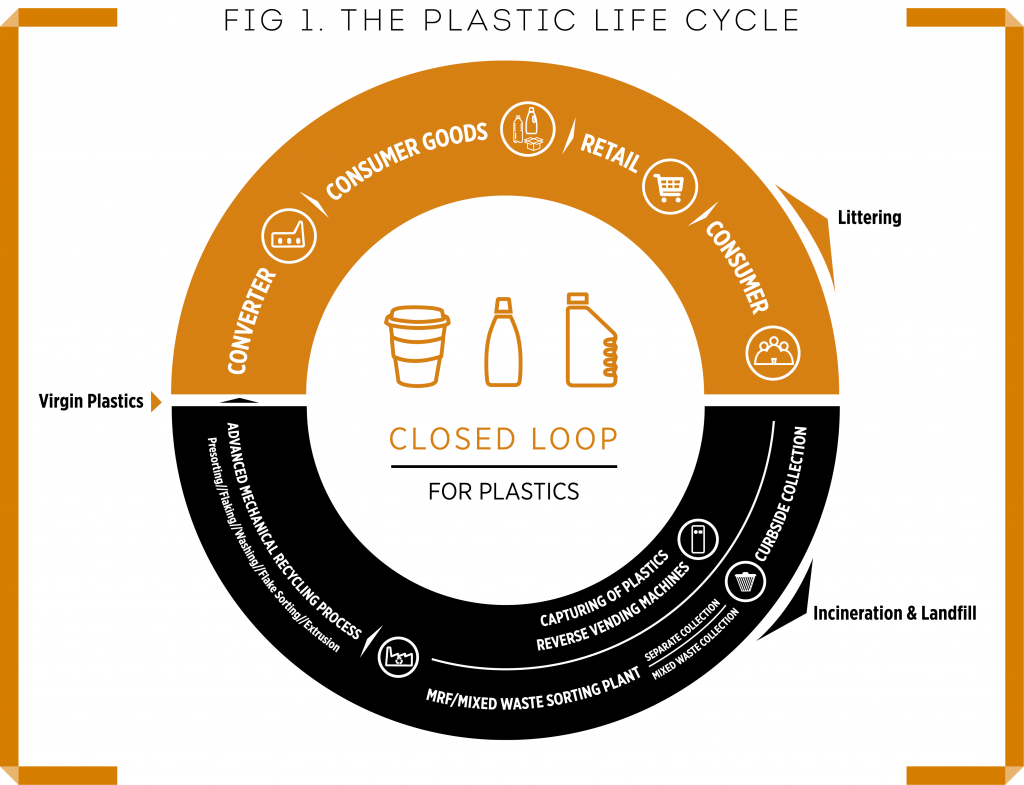

At the heart of behavioural changes and new policies is the need to create a circular economy – one that ensures plastics are handled as efficiently and sustainably as possible. Plastic needs to be kept in a closed loop throughout its life cycle, from production to retail; from the consumer to collection for recycling.

Thanks to its versatility, plastic has become the manufacturer’s go-to resource for production, yet it’s widely treated as being low-value and disposable. This attitude is now changing as we become aware of the environmental impact of the linear economy and develop workable solutions to support a true circular economy. The entire plastics value chain must come together to develop these solutions and bring about changes in behaviour surrounding the material.

When a product is consumed, the packaging typically has no economic value to the consumer, so recyclable material often finds its way into waste streams or the environment

Adopting a circular economy

More than 40 years of mass plastic production means society has adopted a linear usage model – take, make, dispose – leading to plastics being completely mismanaged. In today’s climate, this model has become unsustainable.

A circular economy, or a ‘closed loop’ for plastics, means that plastic materials can be used over and over again for the same or a similar purpose in a continuous loop. A transition to a circular model, where plastics stay in this closed loop and the need to create new plastic is reduced, must take place. This is the core principle of the circular economy: keeping plastics in the loop, and out of the environment.

The plastic supply chain is extremely fragmented, with lots of different stakeholders across multiple countries. Because of this, it’s important to forge robust partnerships.

Many high-profile companies are now signing up to initiatives that have been designed to help make the circular economy more collaborative. For example, the Alliance to End Plastic Waste – which TOMRA joined in 2019 – has more than 30 members. It combines the efforts of one million employees and an investment of $1.5bn over five years to aid the circular economy and invest in innovative projects and technologies to protect our planet.

The European Plastics Pact is a public-private coalition that wants to achieve a truly circular European plastics economy, while both the Circular Plastics Alliance Declaration and New Plastics Economy Global Commitment are also making the circular economy more collaborative. Furthermore, TOMRA and 28 other global companies have joined the HolyGrail pioneer project to investigate how recycling rates can be improved using digital watermarks. What’s important to remember is that there isn’t one solution to enabling a circular economy – collaboration across key stakeholders is vital.

Retail and recyclability

Companies and manufacturers need to make the decision to design their packaging in such a way to facilitate and support recycling, thereby enhancing the value of the material and closing the plastic loop (see Fig 1). By focusing on the end of life of the packaging during design, it can help to maximise its recyclability, ensuring that value is maintained throughout the closed loop, without impacting the product’s aesthetics, cost or practicality. In addition to closing the loop, this also needs to work for brand owners in the retail market.

An important aspect of designing for the end of a product’s life is in the material selection for plastic packaging. Consumer goods manufacturers should avoid the use of toxins, use one single material if possible, and if multiple materials are used, make sure they are easily separable.

Consumers have a vital role in closing the loop as well, both in terms of their purchasing decisions and ensuring that plastic packaging doesn’t end up as litter. They can accelerate the circular economy for plastics by rewarding brands that do the right thing, and by stopping buying goods from companies that don’t. If consumers choose companies that reduce the amount of resources they use, design for recyclability and use recycled materials in production, this will speed up the transition.

Increasing the collection of packaging will also substantially contribute to creating a circular economy. When a product is consumed, typically the packaging has no economic value to the consumer, so recyclable material often finds its way into waste streams or the environment as litter. Plastic needs to retain its value throughout the loop, so introducing legislation and deposit return schemes (DRS) is imperative. Through adding a small deposit to the price of a plastic bottle, which is refunded to the consumer when they return the empty container for recycling, the packaging still has value to the consumer. This gives a clear motivation to return the items for recycling after consumption, making it more likely that the plastic will stay in a closed loop and turn into a new bottle.

A market for recycled materials

Demand for post-consumer recycled (PCR) materials must also be created, because as the demand for PCR increases, so does the value of the material. This makes it more economically viable to recycle.

Brands have a responsibility to lead this change by setting achievable goals for using PCR materials. Unilever plans to halve the use of virgin plastic in its packaging by 2025, while PepsiCo has announced that it plans to use 25 percent recycled content in its plastic packaging by the same year.

To keep materials in a closed loop, there must be a quality focus. Our recycling systems should also be designed to retain the highest value of products, components and materials. A DRS achieves this because the materials are collected separately through reverse vending solutions and container redemption centres, and are not exposed to contamination from other kinds of household waste. This means the plastic materials maintain purity and can be used again and again to make new products.

88%

Maximum reduction in energy consumption by using recycled plastics

25%

Proportion of recycled plastics to be used in EU beverage containers by 2025

Additionally, as the value and demand for PCR materials increases, material recovery facilities will have a greater focus on waste separation due to its economic benefit. This results in higher-quality materials remaining in the closed loop.

The future of plastic packaging

The circular economy encourages a reduction in virgin plastics by reusing the recycled material for product packaging. Using recycled plastics over virgin plastics reduces energy consumption by up to 88 percent depending on the plastic type, making it a far more sustainable option.

New recycling legislation continues to change manufacturers’ approach to plastic packaging, too. Perhaps the most influential piece of legislation to be introduced in the last 18 months was the EU Single-Use Plastics Directive, which set out requirements for all beverage containers to incorporate 25 percent recycled plastics by 2025, and 30 percent by 2030.

It is essential that there is collaboration across all sectors and industries to create a truly circular economy. Partnerships must be built to ensure plastics are recycled and reused as efficiently as possible; today, TOMRA is working to create an ecosystem of partners to help deliver and implement efficient systems. We are communicating with businesses, governments, policymakers and consumers to create awareness around the circular economy, starting a valuable dialogue to provide necessary information about the issue and to create a real impact. For the circular economy to be a success, organisations and consumers the world over must, above all else, work collaboratively.