The shipping industry has dodged a bullet

Ship operators are playing a dangerous game if they wait too long to install exhaust gas scrubbers

It has been more than a year since the International Maritime Organisation (IMO) MARPOL Annex VI Regulation 14 went into effect and, frankly, it appears to be having an immediate and positive impact on sulphur emissions, but is it sustainable?

The amount of sulphur in the air over Denmark has been reduced by over 50 percent since the new sulphur directive for ships operating within the North Sea and Baltic Sea emission control areas (ECAs) was introduced on January 1, 2015, according to the Danish EPA.

There has not been a meaningful enough financial burden on the ship owners to invest in exhaust gas scrubbing technologies

“Sulphur and particles are harmful to humans, so it is good news that the new environmental requirements are having an effect”, said Minister for the Environment and Food, Eva Kjer Hansen. “Denmark is the first country in the world to apply new technology in efforts to monitor pollution from ships and to make sure that everyone is meeting the requirements. The financial benefits of non-compliance with the rules are huge, and control and enforcement are therefore vital elements in preventing harmful pollution from ships and unfair competition for law-abiding ship owners.”

If Denmark is a typical representation of the current sulphur emission experience for the shipping industry then I am pleased and impressed. This is a good thing. This is a very good thing. However, let’s peel back another layer of the onion and dig in deeper and determine how and why the results seem to have been so quickly and easily achieved. Additionally, let’s explore if this positive and encouraging trend is sustainable.

Business almost as usual

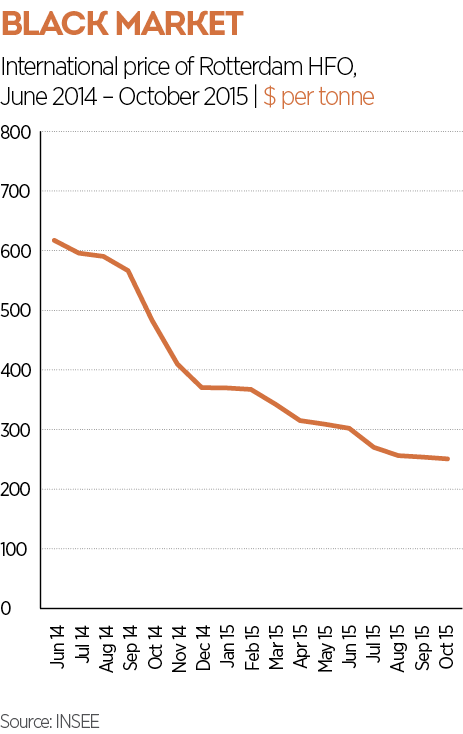

The shipping industry by and large has, at least temporarily, dodged a proverbial bullet due to the dramatic drop in fuel prices witnessed throughout the world in the last year. This drop in fuel expense seems to have given pause and courage to ship owners and removed the ‘urgency’ to outfit their vessels with emission abatement technologies such as exhaust gas scrubbers.

How meaningful has the drop in fuel prices been? As things stand, the cost of Marine Grade Oil (MGO), which would need to be used within ECAs in order to satisfy the current sulphur regulations in the absence of an exhaust gas scrubber, is now cheaper than Heavy Fuel Oil (HFO) was one year ago. To illustrate how fortunate the shipping companies have been in regards to fuel prices since the MARPOL Annex VI Regulation 14 came into effect, a metric ton of Rotterdam MGO is currently about 30 percent cheaper than a metric ton of Rotterdam HFO was one year ago.

What does that mean? It means there has not been a meaningful enough financial burden on the ship owners to invest in exhaust gas scrubbing technologies and they continue to operate as close to ‘business as usual’ as imaginable.

As a refresher, under the revised MARPOL Annex VI Regulation 14, the global sulphur limits applicable in ECAs for sulphur oxides and particulate matter from a ship’s exhaust emissions were reduced to 0.10 percent as of January 1, 2015. Going forward, the global sulphur cap will be reduced from the current 3.50 percent to 0.50 percent, effective from January 1, 2020, subject to a feasibility review to be completed no later than 2018. That means the entire globe is ostensibly going to be an ECA, subject to these emission regulations.

Again, the primary reason that there does not seem to be full blown panic on the part of the shipping companies, in my opinion, is because the pain and cost of doing nothing other than purchasing MGO has thus far not outweighed the capital cost of exhaust gas scrubbing technologies for most ship owners.

Shipping companies and the cruise industry are constantly under pressure. They are under pressure from environmentalists. They are under pressure from global regulatory bodies such as the IMO whose objective is: “As a specialised agency of the United Nations, IMO is the global standard-setting authority for the safety, security and environmental performance of international shipping. Its main role is to create a regulatory framework for the shipping industry that is fair and effective, universally adopted and universally implemented.”

Shipping companies and the cruise industry are constantly under pressure. They are under pressure from environmentalists. They are under pressure from global regulatory bodies such as the IMO whose objective is: “As a specialised agency of the United Nations, IMO is the global standard-setting authority for the safety, security and environmental performance of international shipping. Its main role is to create a regulatory framework for the shipping industry that is fair and effective, universally adopted and universally implemented.”

They are under pressure from competitors both within the industry, and from outside their respective industries by competing methods of transport, or entertainment and travel if they are involved in the cruise industry.

We do not know what the future holds for companies that wait on the sidelines and hope and pray that fuel prices remain low. In order for ship owners to be positioned for corporate survival and financial prosperity in the highly likely event that fuel prices return to previous norms, they need to address their exhaust gas emission issues head on. How do they do this? How do they burn less fuel? What technologies are available to satisfy the existing MARPOL Annex VI regulations? What can they do in a sustainable way to continue to be good environmental stewards?

Our solution

To address this critical issue within the shipping industry, Triton Emission Solutions has designed and developed the NJORD Exhaust Gas Scrubber. The NJORD is a hybrid exhaust gas scrubber capable of being configured to operate in either Closed Loop or Open Loop. The NJORD can be set up either as a standalone exhaust gas scrubber or in combination with the DSOX-20 fuel desulphurisation solution, which can provide additional meaningful benefits pertaining to the removal of heavy metals, etc.

Triton engaged Alten Sweden to do a computational fluid dynamics analysis to verify the design and back pressure expected with the NJORD, and the results have been exceptional; they lead us to believe we have an exhaust gas scrubber with the lowest back pressure of any on the market today, with 11.8 millibars wet.

Triton also believes the NJORD has the smallest footprint of any exhaust gas scrubber available today. Couple that with an in-service installation and we are very confident we have an extraordinary solution for the shipping industry’s exhaust gas scrubbing needs.

As a result of the NJORD’s exceptional design and greatly reduced back pressure, we anticipate that a ship owner could expect fuel savings of approximately four percent. Typical engines on container ships, cruise ships, etc operate at approximately 40 percent efficiency, meaning 60 percent of the fuel burned is wasted in heat and losses.

The NJORD can also be coupled with an optional waste heat recovery system. Waste heat recovery systems are a fantastic way to recover energy that otherwise would have been lost. Technologies exist today that make it possible and practical for ship owners to capture the heat of their exhaust gases and to recover that heat energy and create more efficient use of the fuel they burn. By utilising your fuel more efficiently with the help of a waste heat recovery system, you decrease your overall fuel consumption and fuel costs. By reducing your consumption, you are simultaneously reducing your pollution, reducing your operating costs and optimising the efficiency of your engines.

Remember this simple fact: the most environmentally friendly fuel is the fuel you didn’t have to burn.

For further information, email esandler@tritoninc.com