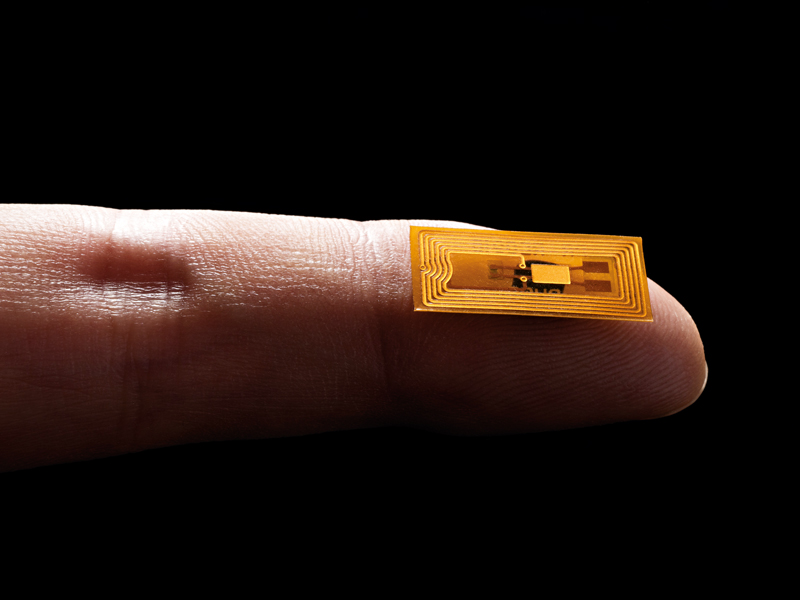

Microscopic ‘smart dust’ sensors are set to revolutionise a range of sectors

Networks of tiny sensors known as ‘smart dust’ are on the cusp of reinventing the Internet of Things. These devices will unlock unprecedented levels of data collection, but their development unearths important security questions

Networks of microelectromechanical sensors, or smart dust, are set to revolutionise the way the Internet of Things functions, transforming a whole range of sectors as a result

The future of computing is microscopic. For decades, technology has followed the same pattern: as speed and capability increase, cost and size shrink. It can be seen in the transformation from the mainframes of the 1960s that filled entire rooms to the bulky PCs that became ubiquitous in the 1990s to the paper-thin laptops, tablets and smartphones we use today.

“Based on that [trend], we should be arriving very soon at millimetre-scale computing systems,” said David Blaauw, a professor of electrical engineering and computer sciences at the University of Michigan, who has spent decades working to miniaturise computing systems.

In 1997, the researcher Kristofer Pister coined the term ‘smart dust’ to describe these millimetre-sized devices. Pister and his colleagues at the University of California, Berkeley, aimed to create a network of sensors made up of tiny wireless computer systems called ‘motes’. Acting as microscopic eyes, ears and arms, these motes could rove around the world collecting all kinds of data: visual, thermal, chemical and biological. In theory, smart dust could revolutionise industries by reaching places scientists never thought possible.

Internet of Things 2.0

Since Pister first presented the idea of smart dust, the concept of building a distributed network of wireless microelectromechanical systems (MEMS) has only gained steam. Although it may sound like a radical concept, smart dust is the natural next step for today’s Internet of Things (IoT). The IoT market has quickly established itself as an essential component of the modern world. Devices vary wildly, from consumer technologies like smart thermostats to products designed for the corporate world, such as small sensors that monitor oil wells to ensure optimised production.

It is unlikely that smart dust technology will trickle down into consumers’ homes before it has penetrated sectors such as industrial monitoring and medicine

In 2017 there were already 27 billion connected IoT devices, but by 2030, research firm IHS Markit expects the number to more than quadruple to 125 billion devices. Dust Networks, a company founded by Pister that is now owned by US semiconductor firm Analog Devices, has successfully deployed one-centimetre scale sensors in several commercial markets, including oil refineries, Pister told The New Economy: “That technology is still selling and being deployed today.”

These sensors have already transformed the way many sectors collect data, but with more advanced and even smaller technology, they could go much further. Not only could smart dust dive into oil wells; it could also sit on the wings of a butterfly to monitor migration patterns or be deployed inside the human body to oversee the recovery process of broken bones or damaged organs.

A number of uses are already being considered: tiny motes of smart dust could be deployed across a farm’s crops to monitor the needs of the plants, from determining watering times to pest control. Elsewhere, smart dust could track bees to find out where they encounter various chemicals that threaten their populations.

In medicine, embedded defibrillators and pacemakers already carry out health-monitoring processes, but smart dust could take that to the next level. Researchers at the University of California, Berkeley, were the first to propose what they called ‘neural dust’ – millimetre-sized sensors that could be implanted in the body and used to stimulate nerves and muscles, as well as to monitor the activity of different organs. In 2016, they successfully built the first of such sensors, measuring three millimetres long, one millimetre wide and one millimetre across.

One day, Blaauw hopes millimetre-scale devices like neural dust could not only take measurements, but also take action. For instance, a project his team is working on involves implanting tiny sensors into tumours to monitor the effectiveness of treatments. “This is very advantageous over blindly treating the tumour,” Blaauw said. “But down the road, it would be great if those little sensors, those little systems, could also themselves provide treatment by emitting certain hormones or medications or other kinds of bio-simulations.”

The construction industry has previously demonstrated success with larger smart-dust-like sensors. For instance, when workers laid the concrete for the basement of One World Trade Centre in New York City, Bill Ray, a research director at the consulting firm Gartner, said they threw sensors directly into the concrete. Throughout construction, the sensors enabled workers to monitor what was going on inside a block of concrete, ensuring that it set properly. By the time the batteries in the sensors died, their job was done. Although these sensors were not millimetre-sized smart dust, Ray told The New Economy that it gives the industry a look at just how varied the different applications of smart dust could be.

In the hands of researchers, smart dust could open the door to innumerable groundbreaking discoveries. “There is actually a lot of information out there that we cannot access… because we’re not small enough,” Blaauw said. “With millimetre-scale systems, we can actually illuminate knowledge into regions of our environment that we just don’t have access to today.”

Weighing up the benefits

It is unlikely that smart dust technology will trickle down into consumers’ homes before it has penetrated sectors such as industrial monitoring and medicine, where motes could more easily be developed at larger scales. But that hasn’t stopped researchers from dreaming up creative uses for consumer-ready smart dust applications.

For instance, Pister envisions a wireless device that he could attach to his fingernails, allowing him to type or sketch anywhere, on the spot. “When we can get down to the one millimetre-scale devices commercially, there are all sorts of fun applications,” he said.

Engineering industry magazine IEEE Spectrum reported details of how smart dust could be embedded into packaged foods so consumers could test whether it was still safe to eat by waving their smartphone over the product. This idea, like many smart dust applications, is only realistic if the technology becomes cheap enough for motes to be disposed of after a single use. Cost, therefore, will be a critical factor holding the smart dust technology back from widespread deployment. “Cost is always a barrier,” Blaauw said. “Definitely right now, these kinds of things, in general, are boutique. They are expensive.” The hope is that, after a chicken-and-egg dance, a company that can tolerate the high initial cost of the technology will drive production up, thus bringing down costs for others.

Number of connected IoT devices worldwide

27bn

in 2017

125bn

by 2030

But companies will only take the leap to a new technology if they can identify a strong return on investment, and currently silicon prices are far too expensive for use in disposable MEMS sensors. IEEE Spectrum calculated that to make one sensor at a cost of $0.01, silicon prices would have to drop by a fifth.

“With a new technology, this is always a tricky part: to identify a killer application that will help drive the final production to volumes where the cost can be low. Then that can springboard many other applications that can then take advantage of that previous investment,” Blaauw said.

Researchers are tackling the cost issue by creating sensors made out of different materials, including paper and plastic. For sensors designed to be put in the body, planted in the ground or used in food packaging, the potential waste caused by the disposal of hundreds or thousands of smart dust motes becomes another issue. To address both of these concerns, researchers at the University of Pennsylvania are working with biodegradable materials, such as those used in dissolvable surgical sutures.

Gathering dust

Before smart dust can radically change the way businesses around the world operate, researchers must first create microsystems that work. Over the past decade, significant progress has been made in shrinking the size of the computing system itself. Blaauw and his team at the University of Michigan have created the Michigan Micro Mote, the world’s smallest computer at just two millimetres wide. During its development, one of the biggest problems the group encountered was reducing the size of the battery.

While shrinking the size of microchips is relatively easy, battery size is dictated by power consumption, and current motes eat up too much power for microscopic batteries. For this reason, many researchers are focused on creating millimetre-scale systems that rely on very low power; when on standby, the Michigan Micro Mote runs on about a million times less power than the average smartphone. Electronics manufacturer Ambiq Micro, which Blaauw co-founded, claims to be the world leader in energy-efficient semiconductor design. The company makes ultra-low-power solutions for IoT devices, wearables and other technologies.

Alongside vast opportunities, smart dust brings sweeping new concerns about privacy and ethics

Researchers are also considering different ways to power smart dust. For instance, the Michigan Micro Mote was able to harvest energy from ambient light via a one-millimetre-by-one-millimetre solar panel. Energy harvesting allows sensors to grab power from a number of external sources, including ambient light, heat or motion. Through ambient backscatter, devices can also take energy from existing radio frequency signals or Wi-Fi. Matrix Industries, for example, focuses on capitalising on ambient heat. The company has already designed a watch that is powered by its wearer’s body heat, and it is also working on systems that capture energy from daily fluctuations in air temperatures.

Sensors used in the body, meanwhile, can be powered by ultrasound technology, which is optimal for hospital use. The researchers behind neural dust, which does not use any batteries, utilise ultrasound vibrations to both power their sensors and read out measurements. “Ultrasound is much more efficient when you are targeting devices that are on the millimetre scale or smaller and that are embedded deep in the body,” electrical engineering and computer sciences graduate Dongjin Seo said in a statement at the time of the announcement. “You can get a lot of power into it and a lot more efficient transfer of energy and communication when using ultrasound as opposed to electromagnetic waves, which has been the go-to method for wirelessly transmitting power to miniature implants.”

No silver bullet

Because of these roadblocks, smart dust could still be decades away from revolutionising the IoT on a commercial scale. According to Gartner’s Hype Cycle, it will take more than 10 years for smart dust to achieve mainstream use. On the graph’s curve, it is at the very beginning of its life cycle, slightly ahead of flying autonomous vehicles.

But the arrival of smart dust will not occur with a big bang. “There are lots of things that will be smart and dust-like on the way to that final destination,” Ray said. Even once the technical kinks are straightened out, the barriers to deploying smart dust on a wider scale could continue to expand. Like any new technological development, alongside its vast opportunities, smart dust brings sweeping new concerns about privacy and ethics. There has already been an outcry over how easily smart home devices can be hacked, and the commercialisation of smart dust would only increase the scale of data being collected by IoT-related products.

Whether it is Google, Amazon or a construction company you have never heard of, the thought of large institutions placing microscopic sensors capable of collecting audio and visual data anywhere they choose brings up a raft of questions around privacy and security: how is that data stored, and by whom? Will consumers be able to opt out of having their data collected?

Experts agree that as long as the issue of security is addressed from the start of the development cycle, it will not be difficult to ensure smart dust is protected from hackers. “[Security] will always be a battle, but even at a sub-millimetre scale there is no reason that dust motes can’t have banking-level encryption and authentication on their communications,” Pister said.

But the trouble with the gradual evolution of new technologies like smart dust is that researchers tend to focus first on making the technology function. Security only becomes a concern when the devices seep into the commercial and consumer markets – and even then, typically after a security scandal occurs. For researchers using smart dust technology to study bees or butterflies, it is easy to see why security is of little concern, according to Blaauw. “But when this technology starts becoming widely used, which is what I think we’re going to see in the next decade or so, then security will have to be added in,” he said.

Nevertheless, the real questions around the security of smart dust are part of a bigger story around data collection and privacy. “We can make [smart dust] secure; technically making it secure is not the problem,” Ray said. “The issue is, how do we decide what level of security we like?” For example, Facebook is a secure system – that, however, has not stopped the social media giant from becoming embroiled in one scandal after another in recent years. These scandals are not about technical security, but about Facebook’s role in sharing data without its users’ knowledge or consent. As Ray explained: “The issue… is not the level of security; it’s the decisions about how to manage that data.”

The IoT industry and social media firms have so far demonstrated how not to approach these complex questions. While 10 years may seem like a long time for business leaders and scientists to tease out the answers to these concerns, it is important that privacy and security are part of the conversation from the start.

Once a security framework is established, smart dust can start to act as the eyes and ears of businesses and organisations. Medical professionals could soon streamline diagnostics and treatments with the help of internal sensors, while a sprinkling of smart dust could allow manufacturers to monitor their inventory from the factory to the shelf. The arrival of networks of minuscule sensors will allow unprecedented levels of data collection. Companies must act before the dust settles on this new era.

Sectors on the front line of smart dust innovation

Industrial monitoring

A number of industrial sectors have already installed networks of small sensors to monitor machinery across a plant or factory. Aside from oil refineries, chemical plants and mines are places where the sensor networks that are already installed could be upgraded to smart dust as soon as the technology is available. As well as monitoring their equipment, consumer goods businesses with large operations (such as packaged-food makers or breweries) could use smart dust to boost inventory control and enhance security by wirelessly monitoring their products.

Medicine

Smart dust has the potential to vastly improve medical treatments and health monitoring by shedding light on what is happening deep inside the body. But even on the surface of the skin, millimetre-scale systems could revolutionise medicine. A process as simple as fitting a prosthetic limb could be improved by using smart dust: by scattering the tiny sensors around the area where the prostheses will attach, smart dust can look out for areas of increased temperature, showing where the stress points will be.

Scientific research

Countless scientific research projects could be kick-started by the emergence of smart dust. In theory, scientists could send a swarm of smart dust to Mars – or even further into space – to collect data on new interstellar frontiers. Back on Earth, smart dust could be used to monitor the conditions of a wildfire or give early warning of a natural disaster like a volcanic eruption or an earthquake. On an even smaller scale, the microscopic sensors could measure – and control – energy or water usage and costs in homes or businesses.