Electro Scan: mastering the dark art of sewer leak detection

Each year, the US’ sewerage infrastructure inadvertently discharges 900 billion gallons of untreated sewage into rivers and communities. Electro Scan’s groundbreaking sewer leak detection technology is greatly reducing that figure

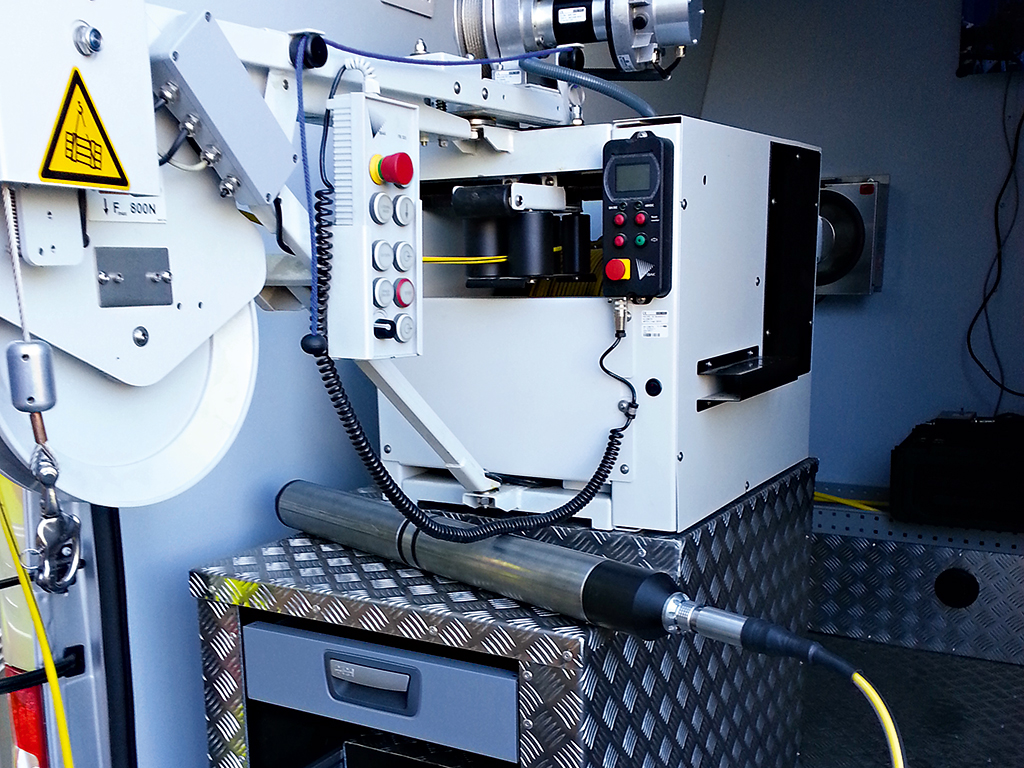

The Electro Scan fitted in a UK CCTV inspection van - the company has completely revolutionised the process of sewer leak detection

Many modern urban sprawls have sewerage systems that date back to the late 19th century. As cities grow, it becomes increasingly difficult to repair and modernise underground networks, but the need for these pipelines to work flawlessly has never been greater. It is therefore no great surprise that sewerage network rehabilitation and maintenance is a huge business in towns and cities, requiring large capital investments as pipelines reach the end of their useful lives.

Water and sewerage systems are vital pieces of infrastructure that make city life possible. While politicians may arrange ribbon-cutting ceremonies at the opening of a new treatment plant, underground pipes rarely get the same fanfare – unless pipes collapse (and gobble up a car or truck) or sewers overflow. The US and most European countries have passed a variety of laws and acts aimed at protecting and managing these resources, and, as a consequence, countries have starkly different approaches to protecting their water networks.

150,000

water suppliers in the US

93%

of US water suppliers service 3,300 people or less

4%

of US electricity is used to power water and sewer system

20-30%

of US water is lost through leaks

“In the US, the Clean Water Act, originally passed in 1972 with major amendments in 1977 and 1987, has become a living document managing and administrating the US water and sewage industry,” explains Chuck Hansen, chairman and CEO of sewer technology provider Electro Scan. “In contrast, Margaret Thatcher made 1989 a watershed year in Britain, by privatising all the water companies: all of the big 10 water and sewer companies (WASCs) went public and sold shares. Now only two remain publicly-traded, as wealthy investors, hedge funds, and international pension funds have bought out UK water companies.”

This has been good news for network management in the UK, where private companies have had to adhere to strict governmental controls. “It’s a very different, almost gentlemanly approach, where a proactive regulator, Ofwat, has controlled investor-owned water companies through a series of multi-year asset management plans,” explains Hansen. Asset Management Programme 6 (AMP6) plans were submitted in December 2013 by all WASCs, undergoing rigorous reviews throughout 2014 by Ofwat to help determine rates, performance levels, and efficiencies for each water and sewerage business. Ofwat says AMP6 will help move the industry forward and eradicate the ‘ticking regulatory boxes’ habit and thereby encourage fresh investment and innovation in the sector.

In contrast, the US water and sewerage industry has been protected through the Clean Water Act, where the Environmental Protection Agency (EPA), working with the Department of Justice has filed Administrative Orders and Consent Decrees to enforce environmental regulations. “The level of enforcement has really ratcheted up during the past several years,” says Hansen. “Billions of dollars in fines and mandatory repair projects have been levied against large and small sewer utilities alike. Today, the EPA is taking a zero-tolerance approach to sanitary sewer overflows and combined sewer overflows, requiring cities to embark on 20- to 30-year programmes of rehabilitation, in some cases mandating out-dated inspection techniques from the 1990s.”

Changing regulations

Due to an evolving regulatory environment, investments in pipe networks and preventative maintenance regimes have become a vital cornerstone of the water industry – and investing in the right type of technology is key. “There’s been a tremendous amount of capital spent on water and sewer networks, and the UK has been a leader in this area,” says Hansen. “Between 1998 and 2010, the UK water industry spent close to £85bn on new plant and equipment.

“If you look at the population of the UK and the US, the numbers tell the story. The UK adopted a centralised structure to oversee 10 WASCs – 12 if you add Scottish Water and Northern Ireland Water, technically still part of their respective governments. In contrast, the US remains highly fragmented with over 150,000 water suppliers, 93 percent of which service 3,300 people or less.”

It’s not uncommon for US cities to operate separate water and sewerage utilities. “We have so many built-in inefficiencies in the US, and such a slow pace of change that it is often difficult to introduce new technologies. Add the slow decay of a crumbling infrastructure where defects cannot readily be detected or seen, and you routinely mismatch assigning needed repairs to your worst pipes.” says California-based Hansen. “Now, after focusing decades on inspecting and repairing sewer mains – the pipes that generally go down the middle of our streets – many US cities are shifting focus to private sewer laterals or side sewers. Yet US cities have little to no control or ownership over these assets. In contrast, the UK boldly transferred responsibility for private sewer laterals to the water and sewer companies in October 2011 – in some cases, doubling the network mileage overnight. Taking responsibility for the majority of the piping network, the UK will be able to take a holistic approach to managing their infrastructure.

“I can see communities spend billions fixing private laterals, thinking they fixed everything they could find in their main sewer lines, only to find their reliance on legacy inspection techniques made them miss the problems in sewers and manholes. By then, sewer bills might have to equal your monthly mortgage payment to pay for all the rehabilitation needed to transport our sewerage.”

Backlog of repairs

Today, cities have a large backlog of the most urgent repairs and maintenance work that need to be done, and the technology used to identify these problems is woefully unreliable. Closed-circuit television (CCTV) cameras have been used to survey pipes for nearly 50 years. Despite a number of advancements, such as higher-resolution cameras, the ability to create a 360-degree panoramic view of the pipe, and the ability to launch smaller cameras from inside larger units to travel up private laterals, shortcomings persist. Recent independent studies and benchmarks have shown reliance on visual inspection of sewer pipes often results in inconsistent or incorrect diagnostics, and, in some cases, prioritising the wrong pipe to fix.

“CCTV does a lot of good things,” says Hansen. “It helps see alignment problems, see a build-up of fats, oils and grease, and see pipe collapses. Unfortunately, CCTV’s inability to be used during wet weather conditions (i.e. when a pipe is full of water), its poor track record in finding leaks or sources of infiltration, inconsistent defect-scoring by operators [whether using UK WRc or US PACP standards], and inability to certify rehabilitation projects as ‘leak-free,’ has given a false sense of security to some utility managers and regulators – frustrating others that are dealing with unexplained or recurring problems in areas already repaired.

A new technology, Electro Scan, has been brought to market by US software pioneer and infrastructure veteran Chuck Hansen, promising a better way to pinpoint defects and certify repairs are fixed.

“We’ve completed hundreds of benchmarks in the US, the UK, Japan, Australia and New Zealand, including several EPA-funded projects that have compared CCTV cameras versus Electro Scan, guided by ASTM F2550-13, an international condition assessment standard. The concern is the alarming number of major cracks and leaks that we are finding with Electro Scan, that never were identified or seen using TV cameras – not to mention, the inconsistent reporting from TV camera operators. It tells us that, if we are relying on findings from visual inspection techniques, then we are risking fixing the wrong pipes.

“In the UK, it is not uncommon for TV operators to abandon 40 percent or more of their camera surveys due to debris, grease or water in the pipe. Crews must pull their equipment out and attempt to televise from the opposite direction, often doubling the work time. Otherwise, surveys are marked ‘Abandoned’ and crews move on to the next pipe. By contrast, Electro Scan’s patent-pending process ‘sees’ through grease and works underwater, many times assessing pipes not able to be televised.

In 30 years, I’ve never seen so many large and small sewer agencies adopt a new technology so quickly

“In 30 years, I’ve never seen so many large and small sewer agencies adopt a new technology so quickly. As a result, our challenge has been to scale our business to serve and support a global customer base.”

Hansen’s Electro Scan offers an alternative approach to pipe condition assessment. It scans pipes for leaks using a low voltage/high frequency electric current where its probe travels rapidly down pipes, recording from 10,000 to 20,000 data points (depending on pipe diameter) every 100 meters, feeding information back to a CCTV truck equipped with Electro Scan’s add-on products. Once data is stored on a field computer, it can be transmitted to a global network of hosted Amazon web servers, where data is processed and immediately available for review on the web.

Hansen was driven to invest and develop Electro Scan after noticing officials were dissatisfied with the results from legacy techniques. “One of our first projects was for a UK water utility that wanted to trial Electro Scan and compare it to CCTV,” he recalls. “Visiting a coastal village, subject to ocean tides, none of the pipes were able to be televised. Either the pipes became full of water at high tide as cracks and leaks allowed water to enter the pipes or cameras got stuck moving through pipes at low tide because silt in the bottom of the pipe was too thick to allow the camera to travel through the pipe. By comparison, Electro Scan was able to scan every pipe.”

Experience in practice

Hansen is by no means a pipeline novice: before Electro Scan he was the founder and CEO of Hansen Information Technologies, a leading provider of asset management applications for water, sewer and highway authorities. He built the company into a multi-million dollar enterprise, selling his business in 2007 and walking away with the majority share of a $100m purchase price to pursue his pilot’s license and a music career that had been put on hold to help the family business. A talented saxophonist, Hansen spent a number of years touring and recording with artists, including Huey Lewis and the News, Eddie Money, and Tower of Power, among others, even releasing his own Christmas single.

However, Hansen was soon drawn back into the pipeline condition assessment game when he heard about the technology that was to become Electro Scan. Originally developed by grants from the German government in the 1990s, the technology was abandoned. “Scan readings weren’t consistent and equipment relied on a portable cable and reel system that was difficult to operate and frequently broke down,” explains Hansen. “In a world of ‘big data’, where large data sets must be automatically processed, calibrated and stored, a key factor in our success was reengineering the solution to ‘plug and play’ with existing CCTV trucks – a platform sewer crews, contractors and utilities are very familiar with operating. Hansen came in, fixed the software – “I’m an old software guy” – adopted the latest cloud-based technology and revamped the technology to fit in CCTV trucks, allowing data to be stored and accessed over the internet.

Hansen stresses that Electro Scan complements existing CCTV technology and is not designed as a replacement. Once Electro Scan has identified leak locations and estimated litres per second (gallons per minute) of leaks, TV cameras are useful to glean more information and get a visual image of what engineers are up against. “Electro Scan looks at a sewer as an electric circuit,” says Hansen. “That means we are applying electrical current inside a sewer pipe, which tend to be made out of brick, cement, clay, concrete, plastic, or resin lining. Since the majority of sewer pipes are made out of non-conductive materials, electricity should not be able to pass through those materials. The only way electricity passes through a pipe wall would be through a leak or crack – however small – but can be measured by Electro Scan.”

Appropriate sewerage and water pipe condition assessment, and targeted repair, replacement and renewal is a major component of city living, especially as utilities such as water and sewerage become more expensive commodities, and urban populations balloon. For Hansen, it goes beyond that; it is an important way in which cities can reduce their carbon footprints and become greener: “Today, over four percent of US electricity is used to power our sewer and water systems, and if we are treating 20 to 30 percent more effluent water than we should – or if we are processing 20 or 30 percent more water than we should for our water distribution system – it is a waste. It is also a major opportunity to reduce carbon footprints, the cost of electricity and to do things in a smarter way.”

“I could not be happier with Electro Scan’s unexpected across-the-board adoption. It’s just too bad I’ve had to keep my horns in their travel cases as the business takes off. Maybe the boss will let me have a weekend free this summer to play my saxes.”