3D printing start-up secures $81m in new funding

Carbon is set to bring 3D printing to the mass production market with investments from big name manufacturers

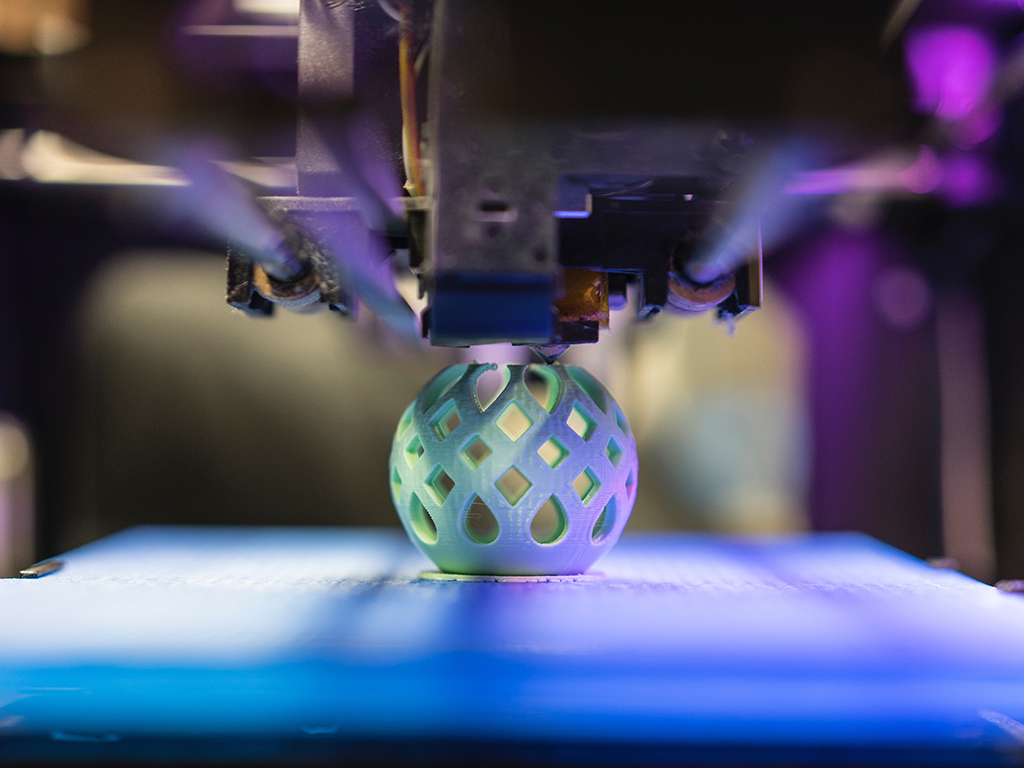

A 3D printer making a plastic bowl. 3D printing is a major force in the manufacturing revolution

Carbon, a 3D printing start-up, has secured $81m in funding from manufacturing giants BMW Group, General Electric, Nikon and JSR Group. The Silicon Valley start-up, which specialises in producing car parts and medical equipment, had previously raised $141m from its existing investors, bringing its total funding to an impressive $222m.

Carbon, whose customers include BMW, Delphi and Ford, has been pushing the boundaries of 3D printing since its formation in 2013. The San Francisco firm claims its flagship M1 machines can produce materials up to 100 times faster than other industrial 3D printers currently available on the market. In addition to focusing on manufacturing speed, Carbon also aims to produce lightweight materials through the use of lattice structures throughout its 3D printed parts.

Carbon claims its flagship M1 machines can produce materials up to 100 times faster than other industrial 3D printers

“3D printing is a translation of the digital to a physical reality and when done right, offers true design freedom across every category”, said Carbon CEO and Co-Founder, Dr Joseph DeSimone.

“At launch we set forth a bold vision to fundamentally change how the world makes ‘things’. We have been working to deliver on that vision for the US market, and are ready to step onto the global stage.”

In securing the support of such big-name strategic investors, Carbon seems set to bring 3D printing technology to the mass production market. Using its multimillion dollar funding, the start-up will be amping up production of its M1 machines, aiming to have 100 operating in the market by the end of the year, and a further 500 available by 2017.

While manufacturers have previously limited their use of 3D printing to creating prototypes, a recent spate of investments in the 3D printing market demonstrates an increasing desire to further integrate the technology into all stages of production.

General Electric has been incorporating 3D printing into its digital technology mission for some years now, investing approximately $1.5bn in the pioneering technique since 2010. Last week, the conglomerate announced it was furthering its ambitions in the sector, acquiring two major European 3D printing firms for a total of $1.4bn.

With high-profile manufacturers beginning to follow GE’s lead in investing in 3D printing, the revolutionary technology may soon become an integral part of large-scale mainstream production.